A new paper is published in the European Journal of Operational Research!

Collection-disassembly-delivery problem of disassembly centers in a reverse logistics network

This paper is a joint work with Jieyu Lei and Ada Che from the School of Management, Northwestern Polytechnical University, Xi’an, China. Download here!

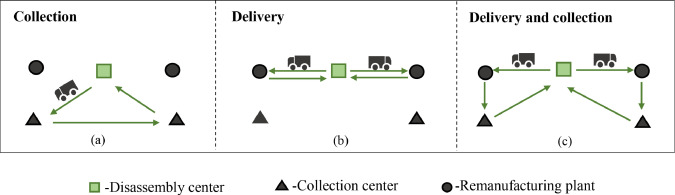

The paper discusses the importance of disassembly centers in reverse logistics networks, essential for recycling end-of-life products like vehicles, batteries, and electronic waste. These centers work with collection centers and remanufacturing plants to achieve high recycling rates. The paper introduces a new problem called the Collection-Disassembly-Delivery Problem (CDDP), which aims to integrate decisions related to disassembly, inventory, and vehicle routing at a disassembly center.

In recycling end-of-life electric vehicle (EV) batteries, a disassembly center could use the Collection-Disassembly-Delivery Problem (CDDP) model to optimize its operations. Collection centers would gather used batteries from consumers and then send them to the disassembly center. The batteries are broken down into valuable materials like lithium, cobalt, and nickel. These materials are subsequently sent to remanufacturing plants to be made into new batteries. The CDDP model assists the disassembly center in making integrated decisions on how many batteries to disassemble daily, how to manage inventory, and how to optimize vehicle routing for collection and delivery tasks. By applying the mixed-integer linear programming (MILP) model proposed in the paper, the center can minimize its total operational costs by using the same fleet of vehicles for collecting and delivering, thereby achieving greater efficiency and cost-effectiveness in the reverse logistics network.

While there has been extensive research on integrated decision-making in forward supply chains, there is a lack of focus on disassembly centers in reverse logistics networks. Previous studies have looked at collection and disassembly but have ignored the delivery aspect of remanufacturing plants. The paper proposes a mixed-integer linear programming model (MILP) to address the CDDP. This model aims to minimize the cost incurred by the disassembly center by optimizing decisions related to disassembly, inventory, and transportation. The paper suggests that disassembly centers can reduce transportation costs by using the same fleet of vehicles for both collecting products and delivering materials. This is illustrated through a simple vehicle routing decision model.

The paper improves upon existing heuristic approaches to solve the MILP model for CDDP. It introduces a tabu search procedure and an adaptive large neighborhood search heuristic, enhanced with a learning mechanism and new removal operators. The CDDP model and the associated heuristics can be applied to real-world scenarios, as demonstrated through a real case and three datasets.

In summary, the paper addresses a gap in the literature by focusing on the integrated decision-making required at disassembly centers in reverse logistics networks. It proposes a new problem (CDDP) and offers a mathematical model and heuristic methods to solve it, thereby contributing to theory and practice.